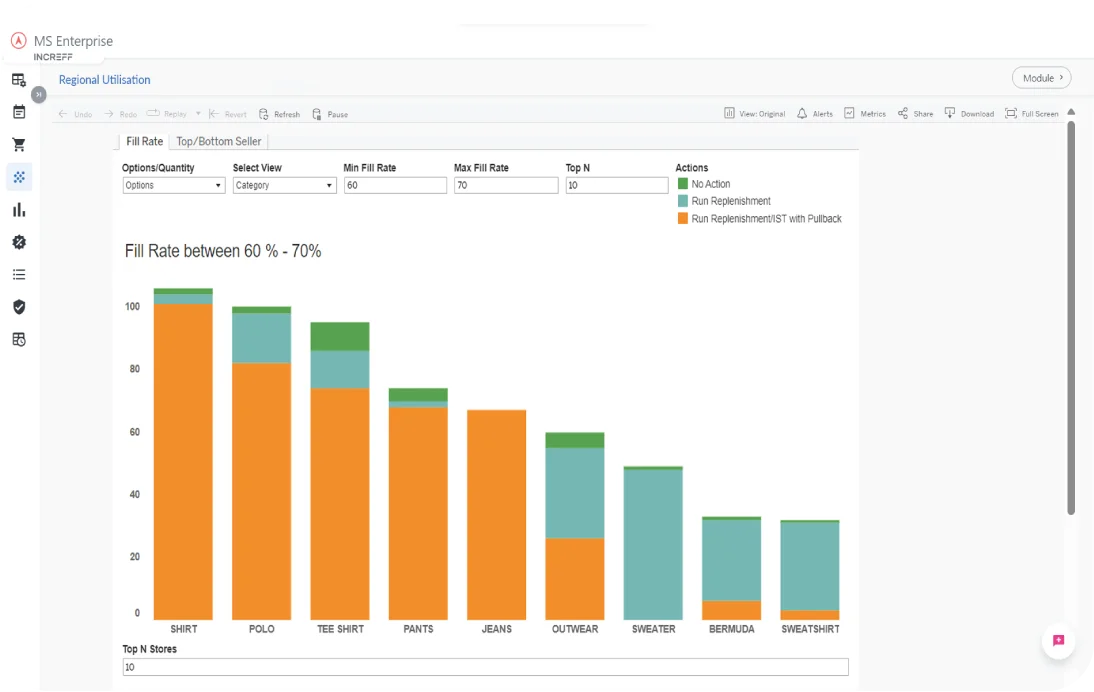

Regional Utilization

Optimize inventory distribution in a multi-warehouse network. Enhance proximity to customers, minimizing delivery time and logistics expenses effectively.

12%

Savings in logistics cost

30%

Faster deliveries of orders

70%

Air shipments converted to surface

100%

Accurate new warehouse recommendations

Features of Multi Warehouse Inventory Management

Enhance customer proximity using data for maximum conversion

Customer pincode level demand pattern

New style distribution

Demand-based inventory distribution

Warehouse capacity and target cover consideration

Available for offline stores

Value we add

- Enhance marketplace visibility through local demand optimization leading to increased conversions

- Reduce inventory returns by timely order fulfillment and enable rapid re-commerce

- Drive sustainability by reducing air transport and excess inventory waste

- Enable faster and more flexible deployment with country-wide processing

Explore Similar Merchandising Software Solutions

Case Studies - Merchandising Software Solutions

A Leading Sportswear and Lifestyle Brand Achieved 10% Improved Inventory Health Through Algorithm-Based Inter-store Transfers

It’s almost impossible to sell deadstock after an EOSS sale. WRONG.We, at Increff found a way. We recently...

The Perfect Match with Increff

A rapidly expanding fine jewelry brand, specializing in silver, gold, and lab-grown diamonds, it swiftly...

Inventory Optimization: Increff<>Jaypore

Jaypore, a brand under Aditya Birla Fashion and Retail, utilized Increff Merchandising Software from...

Revolutionizing Supply Chain Operations: Increff <> Globalbees

GlobalBees is one of the leading e-commerce aggregators in India with a portfolio of 55+ D2C brands....

The Indian Garage Co.: Scaling New Heights in D2C Fashion with Increff

The Indian Garage Co. (TIGC) has established itself as a trendsetter in India’s D2C fashion landscape....

Damensch Optimizes Warehouse Management with Increff

Dedicated to excellence, Damensch stands out as a premier menswear brand, celebrated for its fusion of...

Puma Enhances Warehouse Operations with Increff

Puma, a renowned global sportswear brand celebrated for its groundbreaking and high-performance athletic...

A celebrity-endorsed fashion brand increases full-price sell-through by 13% with a smart assortment plan

Optimized inventory through the smart assortment planning for different sales channels. One of India’s...

One of the trendiest retail brands builds efficiency in Warehousing to achieve ~50% reduction in manpower cost

One of India’s largest retail brands and the powerhouse of some of the trendiest and exclusive international...

Global Footwear giant improves inventory turns by 2-3x with easy Multi-system Deployment

One of the world’s leading sportswear brands was facing operational hassles working on multiple systems...